Featured Article from

Audiophile Q&A: Turntable, Direct-drive versus Belt-drive (or, it just depends…)

Phillip Holmes

When properly adjusted and maintained, there are many, many, turntables that can get the job done: spinning a record, at a consistent speed, without introducing noise. Some designs are more stable than others, some require an extraordinary amount of diligence when it comes to set-up and maintenance (something I like to avoid).

Several things to point out are:

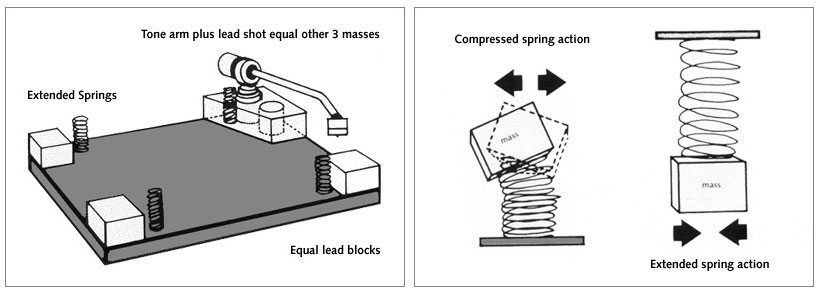

Belt-drives tend to modulate a spring-suspended sub-chassis.  It’s something I noticed with several tables I’ve used.  I’m speaking specifically of players where a sub-chassis sits on top of three cone-shaped springs that are compressed by the weight of the platter/bearing/sub-chassis.  The springs are there to isolate the sub-chassis from acoustic feedback.  The belt is meant to isolate the platter from the cogging of the AC synchronous motor.  If you recall the little playground animals that sit on re-purposed automobile coil springs, you might understand a basic design flaw.  Just as the child will oscillate to-and-fro on the spring, the coil spring suspension in a turntable has the tendency to be unstable.  As soon as the child gets on the animal, it starts to roll and deflect to the side.  Unlike an automobile that puts the spring in the middle of a suspension which limits the possible motion of the spring, the playground animal (and turntable) is unstable. My first vinyl rig was a rebuilt and modified AR-XA.  It had a dinky little AC synchronous motor driving a sub-platter with a rather loose belt.  If the record was pressed off-center, which is very common, the back-and-forth movement of the cartridge caused a modulation in the sub-chassis.  There were different tweaks to be tried, but the design was always unstable.  There are many similar tables, some better than others.

A better solution was SOTA’s introduction of something that seems rather obvious: hanging/dangling the sub-chassis from the springs.  Because they hang the sub-chassis from four springs, it always wants to return to equilibrium when put into motion.  The weight of the sub-chassis is pulled straight down by gravity, so there is only one position where it will be stable, and it will always return to that position.  Think of it like a pendulum.  Once the pendulum stops moving, it will be “pointing” down to the center of the planet, the source of gravity.  If the pendulum were somehow perfectly balanced and pointing up, it would take only the slightest input of energy to throw it out of balance and cause it to fall, where it would eventually stabilize pointing straight down.  SOTA also used a more sophisticated motor, motor-drive electronics, and cast-rubber belt driving the periphery of the platter.  The platter’s mass was concentrated at the outside edge, giving it better “flywheel effect”. The result was better speed stability than previous belt-drive systems.  I owned a Sapphire for a long time.  It made good on the promise of speed stability and isolation from outside noise.

|

| Illustrations courtesy of SOTA Turntables |

| more… | page 2… |

| About Dagogo.com |

| DAGOGO (pronounced “dah-go-go”) is a U.S. high-end audio review monthly e-magazine established since November 2003. Its mission is to present both a macroscopic and microscopic view of the high-end audio hobby to its readers. Its contents include critical commentaries, industry personality interviews, specialty show coverages and music reviews. New articles are published on the 1st and 16th of every month. www.dagogo.com |

Leave a Reply